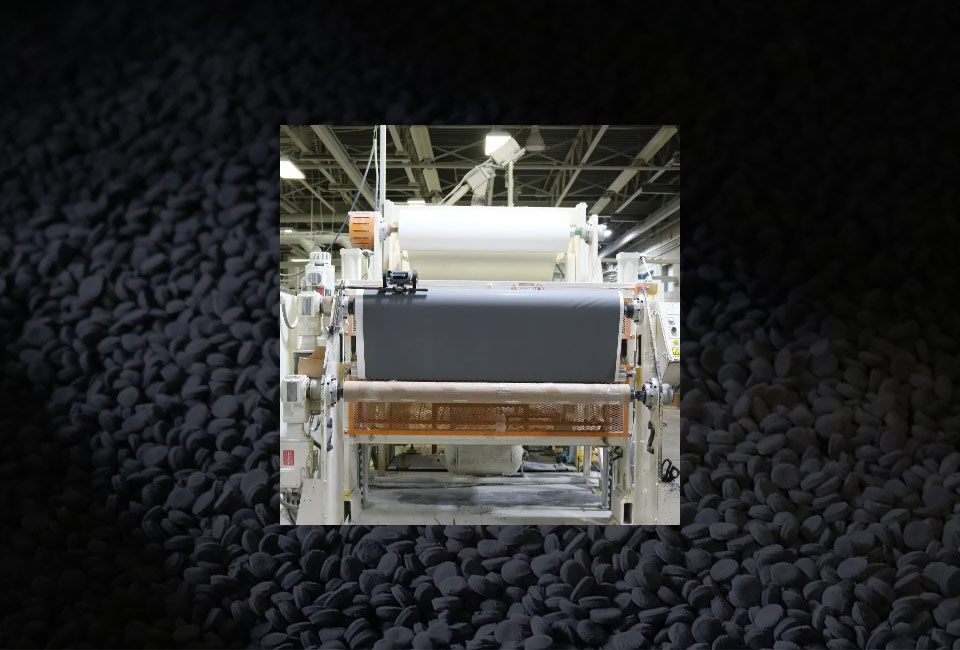

How Our Attenuation Material is Made

When it comes to attenuation materials, Complete Medical Australasia offers a variety of options using two distinct processes: curing or extrusion. These different manufacturing processes each result in unique qualities and benefits.